🥂 Broke a Glass? Someday You Might 3-D-Print a New One

The vision of instantly replacing a broken wine glass by hitting “print” is moving closer to reality, thanks to breakthroughs in 3D-printing glass—a field once considered nearly impossible due to the material’s complex thermal and optical properties.

While consumer desktop printers aren’t ready to handle molten silica just yet, researchers are developing several innovative methods that are already transforming high-tech manufacturing, with future potential for wider application.

The Challenge of Glass

Glass is an amorphous material, meaning it lacks the rigid crystal structure of most metals and plastics. It transitions from a liquid to a solid state over a wide temperature range, and its high processing temperature—often exceeding $1,000^{\circ}C$ ($1,832^{\circ}F$)—makes it challenging for conventional 3D-printing techniques.

Innovative 3D Printing Methods

Researchers have developed several pathways to overcome these challenges:

- High-Temperature Extrusion (Molten Glass):

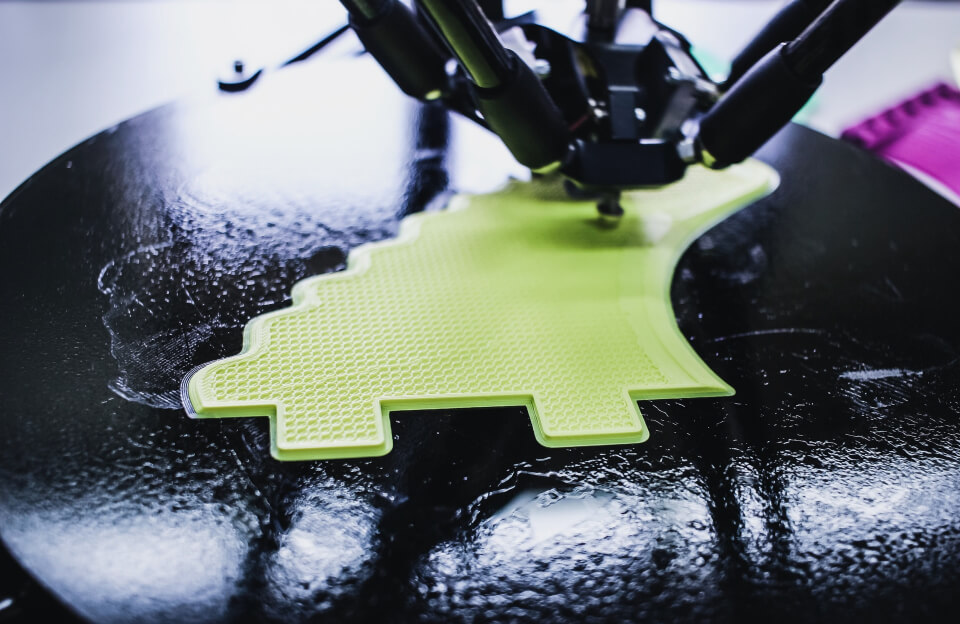

- This method is conceptually similar to Fused Deposition Modeling (FDM) used for plastics. Molten glass (often derived from recycled bottles) is heated to extremely high temperatures (around $1,300^{\circ}C$) and extruded through a nozzle layer by layer.

- This technique is currently used to create architectural components and unique art pieces, demonstrating the ability to recycle glass waste into complex, structural forms.

- Stereolithography (SLA) with Silica Resin:

- This is a leading method for creating high-resolution and optically clear glass objects, especially for microscopic applications.

- The printer uses a special resin or ink composed of silica nanoparticles suspended in a light-sensitive polymer binder. A laser or digital light projector (DLP) solidifies the shape.

- The printed object (called a “green body”) is then subjected to a heat treatment (sintering) that burns away the polymer and fuses the nanoparticles into solid glass. Researchers are consistently lowering the necessary curing temperature to make this process more accessible.

- Low-Temperature Direct Ink Writing (DIW):

- New techniques, such as those developed by researchers at MIT, focus on creating custom “glass inks” made of inorganic materials and a silicate solution.

- These inks can be extruded at or near room temperature and then cured at a relatively low temperature (around $250^{\circ}C$), which is essential for printing glass directly onto temperature-sensitive microelectronic components without damaging them.

Future Applications

The ability to 3D-print glass with precision and complex geometry is opening doors in critical fields:

- Optics: Rapid prototyping of custom micro-lenses, filters, and waveguides for compact cameras, medical endoscopes, and virtual reality headsets.

- Biomedical: Creation of precise, implantable glass scaffolds or “lab-on-a-chip” microfluidic platforms for chemical analysis.

- Architecture & Design: Producing unique, load-bearing glass bricks and customized facade elements with intricate internal structures.

While you won’t be printing your own glassware at home tomorrow, the technology is rapidly advancing from the lab bench into commercial applications, confirming that the future of glass manufacturing is additive.

I can search for videos showcasing the molten glass 3D printing process if you’d like to see this amazing technology in action.